Plastic plywood is a sustainable alternative to traditional plywood which is used so frequently in construction projects and DIY. It has all the benefits of traditional plywood despite being made of 100% plastic. As a result, it maintains a consistent strength when exposed to the ground and harsher weather. It is all around more durable and resistant to rot. Sometimes it can be tricky to find the right tool that achieves the perfect cut on new materials. It is fortunate that plastic plywood is just as workable as the regular type. As a result, a SMART Fine Tooth Blade can smoothly cut it down to size.

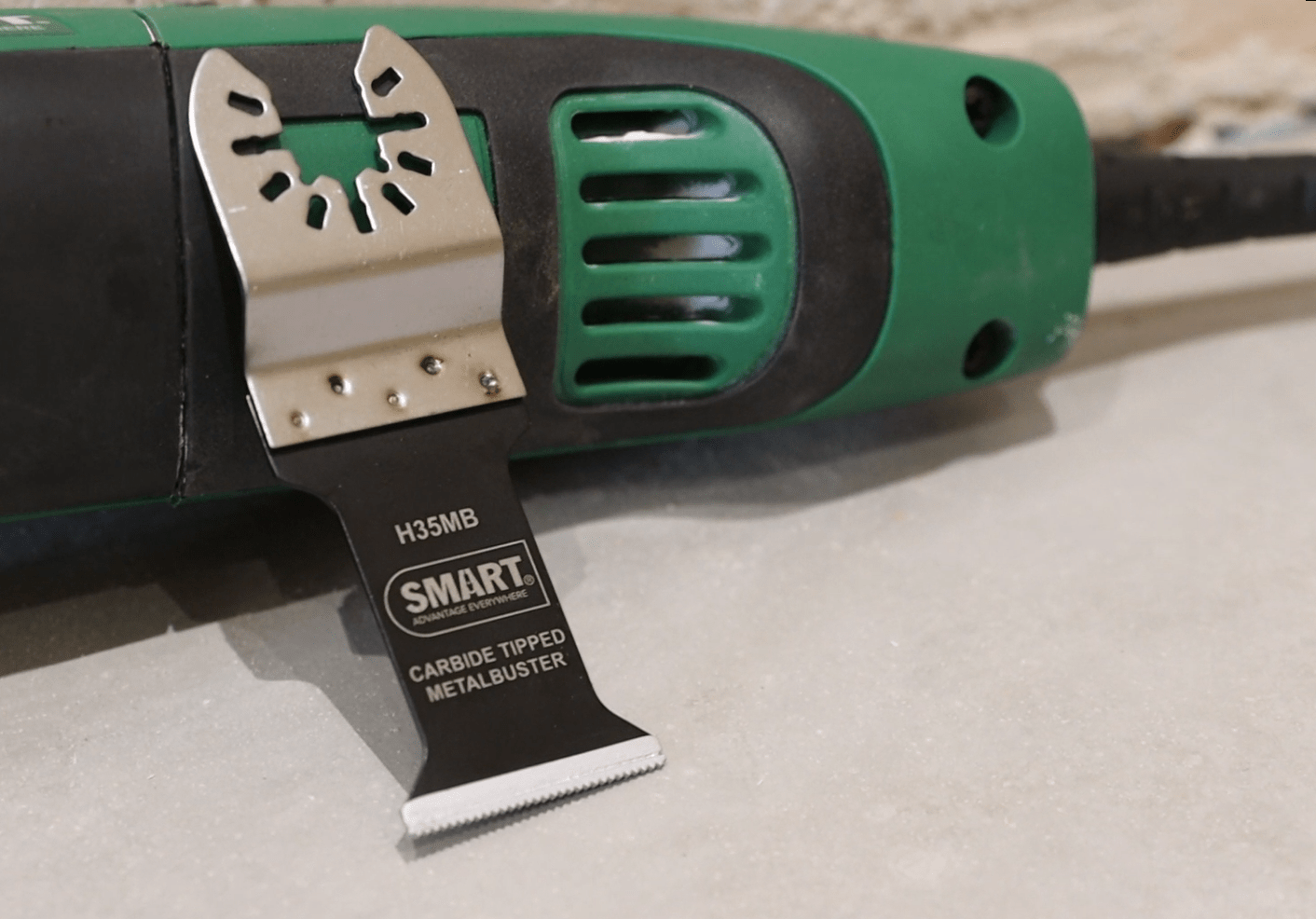

The SMART 32mm Fine Tooth Blade is the perfect multi-tool accessory for making intricate cuts for precision work. The tooth formation provides a clean result every time. It is part of the wider SMART Fine Tooth Blade range and is available for both standard fitment multi-tools and Starlock fitment multi-tools. This range is designed to cut through both wood and plastic; therefore, it is ideal for plastic plywood. Also, unlike some tools, even when in motion, the blade will not become hot enough to melt the plastic.

All SMART Fine Tooth Blades have a potential plunge cutting depth of 42mm. Alternative 63mm Fine Tooth Blades are also available. Both sizes are sold as either a single blade pack or as a set of three or ten.

1. Measure and pre-mark your cuts

This stage is key when working with the SMART Fine Tooth Blade. Precision cuts can only be as accurate as the planning that goes into them.

2.Attach the blade to the multi-tool

When satisfied with the planning stage, attach the Fine Tooth Blade to your Multi-Tool.

3.Cut the plastic plywood to the desired size

When cutting, ease the multi-tool into the plastic plywood. The material will not splinter as much as regular plywood might. Therefore, let the multi-tool and the blade attachment do the hard work for you. Keep a keen eye on the blades positioning and focus on achieving the cleanest cut.

4.Clean away the dust and debris

Brush away the excess and you should have achieved the perfect cut.

Find your local SMART Stockist today!

SMART is always on the lookout for ways to make our user’s lives easier. Drywall may not....

Our long running SMART video series “101 Uses for a Multi-Tool” will be returning late....

For over a decade, SMART has risen through the ranks of the multi-tool accessory market. W....

We at SMART are always looking to provide new solutions to your problems. That is why the ....