For decades, copper was one of the go-to materials used for plumbing pipes throughout the country. It was a tried and tested material for the job. Suitable for hot and cold temperatures as well as offering corrosion protection. While copper is being increasingly replaced as the standard for pipes by alternatives such as polyethylene flexible tubing (PEX). Copper piping remains as one of the common obstacles faced by tradespeople working in buildings, especially for jobs such as renovating bathrooms.

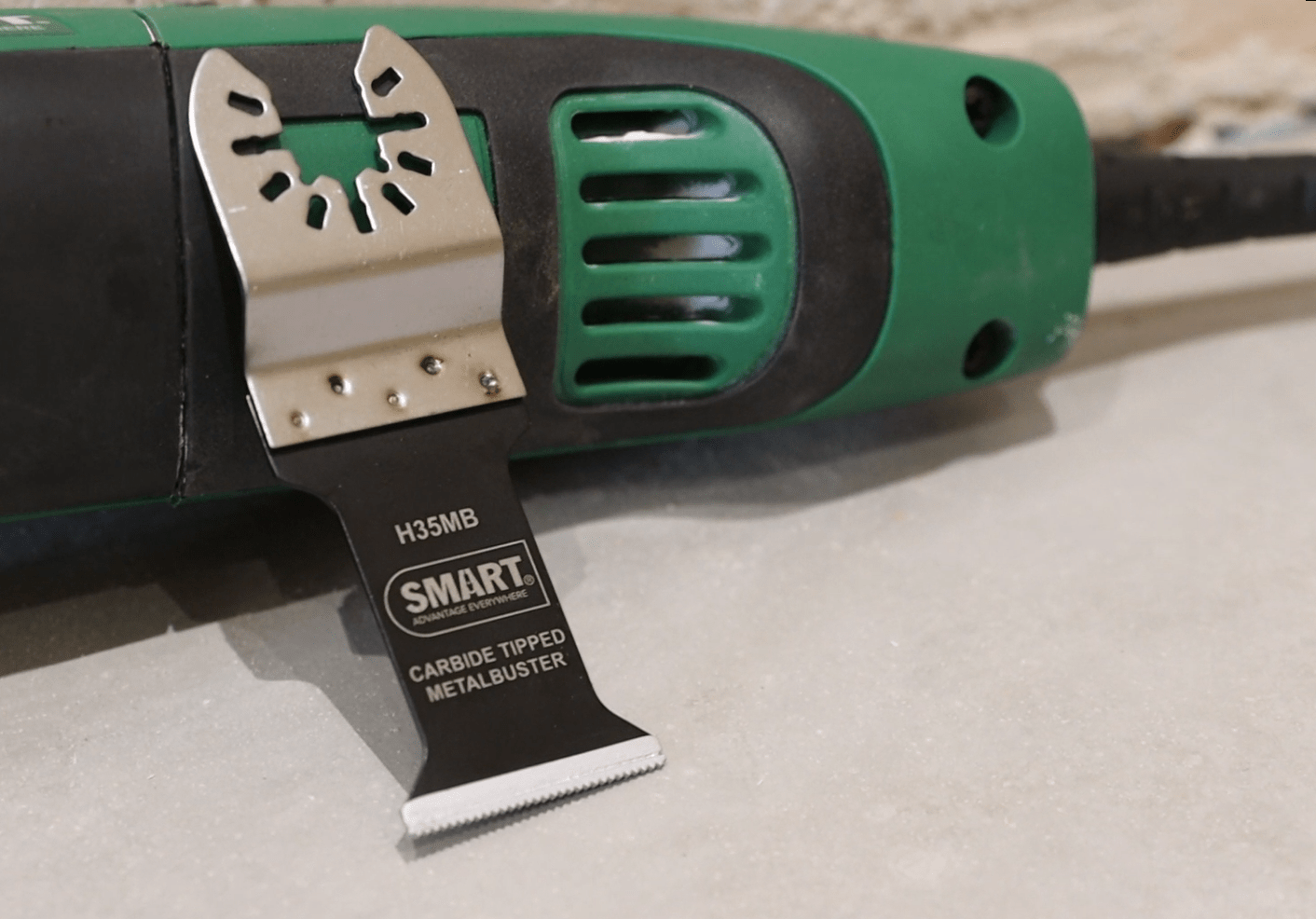

During a renovation, removing tiles and peeling back a bathroom wall to the raw plaster may start to reveal the piping underneath. This will need to be removed before the wall can be made flat and improvements can properly begin. To do so, parts of the copper pipes may need to be cut down to size, and the larger fittings removed. While a common go-to tool in most circumstances may be simple pipe cutters, a multi-tool will provide an easier solution. With the pipes being embedded in the wall, it may be difficult to maneuver and secure leverage with pipe cutters. Therefore, in these narrow and awkward spaces, a careful flush cut with a multi-tool will achieve better results. The SMART 35mm Metal Cutting Blade, or “Metal Buster”, is the perfect multi-tool attachment for applications like this.

The 35mm Metal Cutting Blade is an attachment equipped with incredibly tough tungsten carbide toothing. It gains its name from the impressive way it can bite through steel, hardened screws, and other thick metal as well as fiberglass and more. This makes jobs containing things made of non-ferrous metals, such as copper piping, a breeze for the “Metal Buster”.

Tungsten carbide is a popular choice of material for cutting blades and drill bits. The rigidity of the metal makes it tougher than other alternatives. It can endure high-speed cutting that generates lots of heat. This results in a blade that will not be dulled when faced with cutting strong materials. The SMART “Metal Buster” Blade is available for both universal and Starlock fitment multi-tools.

1. Tear back layers of the wall to reveal the copper pipes

2. Attach the Metal Buster Blade

Snap either your universal or Starlock attachment to your multi-tool.

3. Cut through the pipe

Let the metal buster earn its name, the tungsten carbide toothing will make short work of the pipe. The blade is built to withstand cutting through thick metal so any larger fitments will not be a concern.

4. Remove the pipework

5. Fill in the wall

Once filled and smoothed over, you can proceed with further work.

Reminder – Always wear the correct PPE when operating a multi-tool.

Find your local SMART stockist today!

SMART is always on the lookout for ways to make our user’s lives easier. Drywall may not....

Our long running SMART video series “101 Uses for a Multi-Tool” will be returning late....

For over a decade, SMART has risen through the ranks of the multi-tool accessory market. W....

We at SMART are always looking to provide new solutions to your problems. That is why the ....